AI enhances engine inspection processes and predictive maintenance

Artificial intelligence has begun to permeate just about every aspect of GE Aerospace’s business as the engine and aircraft systems manufacturer looks to boost efficiencies while continually improving its products.

Over the past decade, the U.S.-based group has established one of the largest portfolios of AI-related patents in the aviation industry, and it employs more than 100 specialists focused on AI and data science, according to David Burns, the company’s chief information officer.

“We’re also very humble to the fact that we’ve got a lot that we will continue to learn,” Burns told reporters during a briefing at the company’s Cincinnati headquarters in June. “We’re on a learning journey, and we’ve got to make sure that our pace of learning keeps up with the pace that technology is evolving.”

GE already has determined how to incorporate machine-learning models into automated inspection processes and predictive maintenance services. However, generative AI “is an area where we don’t have as much experience,” said Burns, “so we’re really looking to build out some of those capabilities.”

Generative AI models like Chat GPT use existing data to create new and original content such as text, images, and videos. Some in the aviation industry have suggested that generative AI could someday design entire aircraft. For now, GE Aerospace concentrates on using generative AI for more pragmatic short-term solutions, like helping software developers generate code, explained Dinakar Deshmukh, vice president of data and analytics at GE Aerospace.

Deshmukh said his team of software developers recently has been experimenting with a generative AI application that has shown promising results, with individual productivity increasing and software development life cycles accelerating.

Predictive Maintenance

On the customer service side, GE Aerospace uses AI for predictive maintenance, applying data to predict maintenance issues before they become problematic. The company operates remote monitoring diagnostics centers in Cincinnati and Shanghai, where engineers monitor engine data around the clock to detect potential issues.

GE collects data from all 44,000 of its in-service engines during every flight. It combines that data with physical models and environmental details to predict maintenance issues before problems arise, said Jayesh Shanbhag, GE’s vice president of customer experience.

“[For example], we are able to detect through analytics and through AI models an anomaly on an oil filter sensor [if] the signal that we are getting back is not in the normal parameters, Shanbhag. “We run those models automatically and are able to generate an alert for the maintenance team of an airline,” who can then address the issue, Shanbhag explained.

This engine-by-engine, analytics-based maintenance system helps operators to reduce the lifecycle cost of ownership and keep their assets flying with high utilization, Shanbhag said. GE provides the feature as a basic support service for all of its airline customers at no additional cost.

Enhanced Inspection

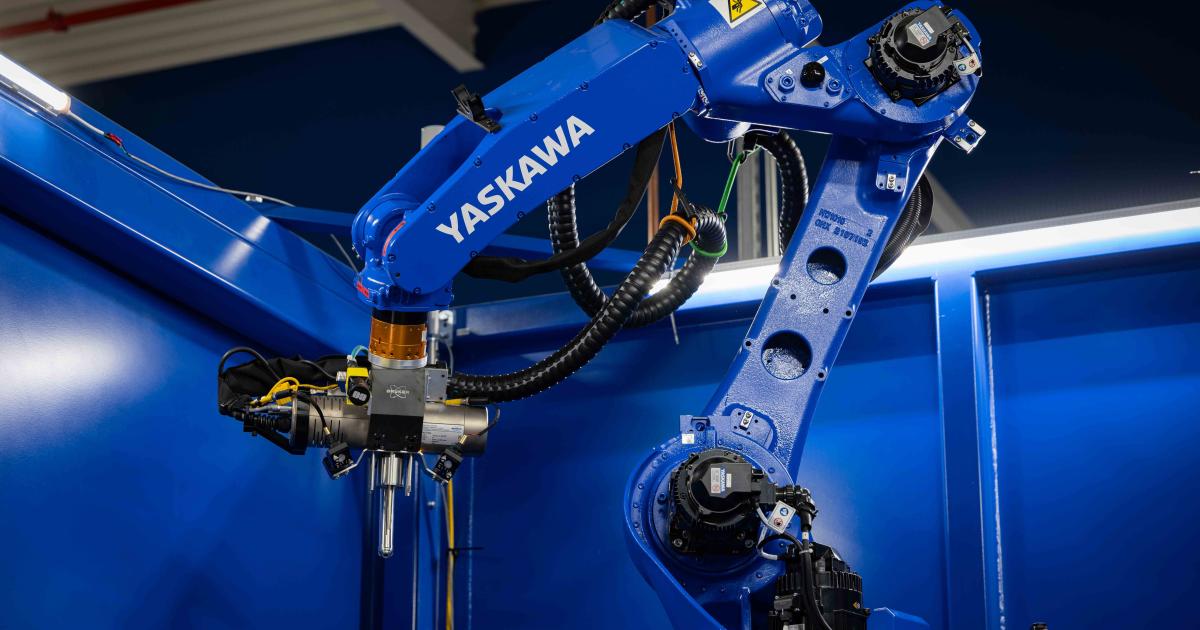

GE Aerospace is also implementing AI in its engine inspections for manufacturing as well as maintenance, repair, and overhaul (MRO) activities. The company already uses robotics to automate inspection processes and capture standard images. Now it feeds those images to machine-learning models to train the AI algorithms that power GE’s analytics-based maintenance program.

“Digital inspection [and] standard image collection allows us to apply advanced machine learning and AI models to really drive a better outcome for our customers,” said GE Aerospace chief MRO engineer Nicole Jenkins.

“We like to support our customers throughout the lifecycle of the engine,” she explained. “That means not only applying AI when the asset is with the customer and in service, but all the way down to the piece-part or repair level once the engine is in the shop and fully disassembled.”

To further advance its inspection and repair processes, GE Aerospace plans to open a dedicated facility in Cincinnati called the Services Technology Acceleration Center (STAC).

Scheduled to open in September, the STAC facility will feature a new inspection device that uses nondestructive X-ray fluorescence spectroscopy (XRF) to detect structural variations inside metal parts. The XRF inspection device, which GE developed in partnership with Bruker, uses the same technology that museums and art collectors use to identify forged artwork. It provides a detailed snapshot of an object’s chemical composition, making anomalies easier to detect.

XRF inspections can also help to alleviate ongoing supply chain constraints, as they can more clearly delineate airworthy repaired parts that might otherwise be replaced unnecessarily.

Russel Stokes, president and CEO of commercial engines and services at GE Aerospace, said the company continuously strives to use AI, data analytics, and robotics to improve performance through its shops with white light inspection, allowing it to automatically see crack propagations in parts to be able to better disposition that hardware or to actually perform different levels of repair capability in shops.

Burns explained that GE’s approach to AI centers around three core principles: using trustworthy data, making models transparent, and keeping humans involved in the process. “We’ve got to ensure that everything we’re putting through artificial intelligence is built on a foundation of solid data,” he said. “AI is great to bring decision recommendations [and] insights forward, but we’re really focused on making sure we’ve got humans in the loop on everything we’re doing with AI.”